Study Notes

Overview

This study guide provides a comprehensive overview of Applying Safe Food Storage and Handling Techniques, a critical area within WJEC Component 1. Success in this topic hinges on a candidate's ability to move beyond common sense and apply precise, scientific principles to practical kitchen scenarios. Examiners are looking for the integration of microbiological knowledge—specifically how temperature, time, and moisture affect bacterial growth—with the operational steps of storing, preparing, and serving food safely. A high-scoring response will consistently reference critical control temperatures, demonstrate a clear understanding of cross-contamination vectors, and correctly apply the '4 Cs' (Cleaning, Cooking, Chilling, Cross-contamination) framework. This is not just about memorising rules; it is about explaining the scientific reasoning behind them to justify safe practices, a skill that directly maps to the high-tariff AO1 and AO2 assessment objectives.

Key Principles of Food Safety

Temperature Control

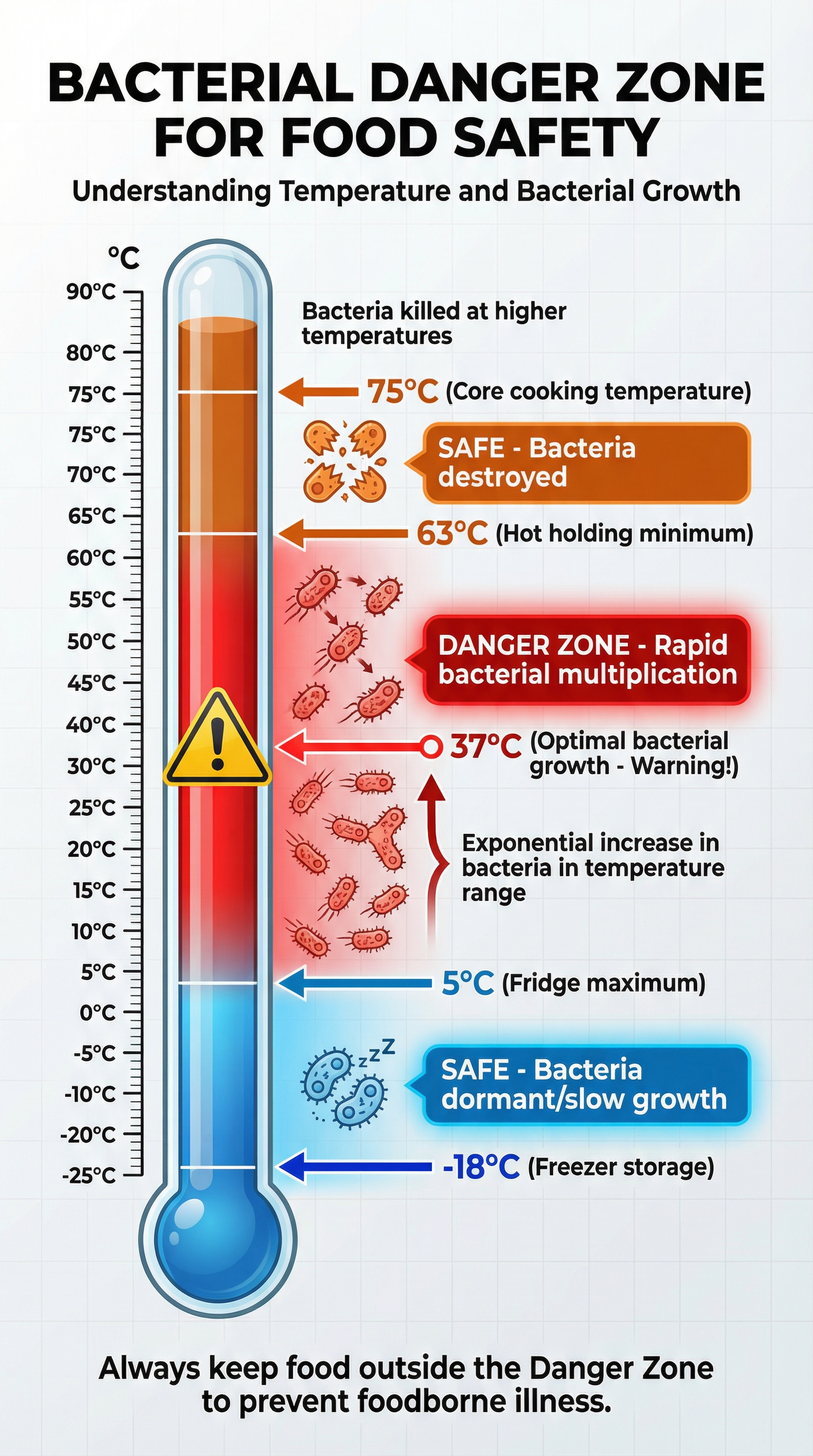

Why it matters: Temperature is the single most effective tool for controlling microbial growth. Examiners expect candidates to know and apply specific critical temperatures, as vague terms like 'hot' or 'cold' will not receive credit.

Specific Knowledge: Candidates must be able to recall and explain the significance of these temperatures:

- -18°C: Standard freezer temperature. At this point, bacteria are dormant; their metabolic processes and reproduction (binary fission) are paused. It is a common misconception that freezing kills bacteria—it does not.

- 0°C to 5°C: Recommended refrigerator temperature range. This is the 'safe chill zone' where the growth of most pathogenic bacteria is significantly slowed. The legal maximum is 5°C.

- 5°C to 63°C: The Temperature Danger Zone. Within this range, bacteria multiply rapidly. The most rapid growth occurs around 37°C (human body temperature).

- 63°C: Minimum hot holding temperature. Food held for service (e.g., in a school canteen) must be kept at or above this temperature to prevent bacterial multiplication.

- 75°C: The critical core cooking temperature. Reaching 75°C for at least two minutes is effective at destroying most pathogenic bacteria, making the food safe to consume.

The 4 Cs of Food Safety

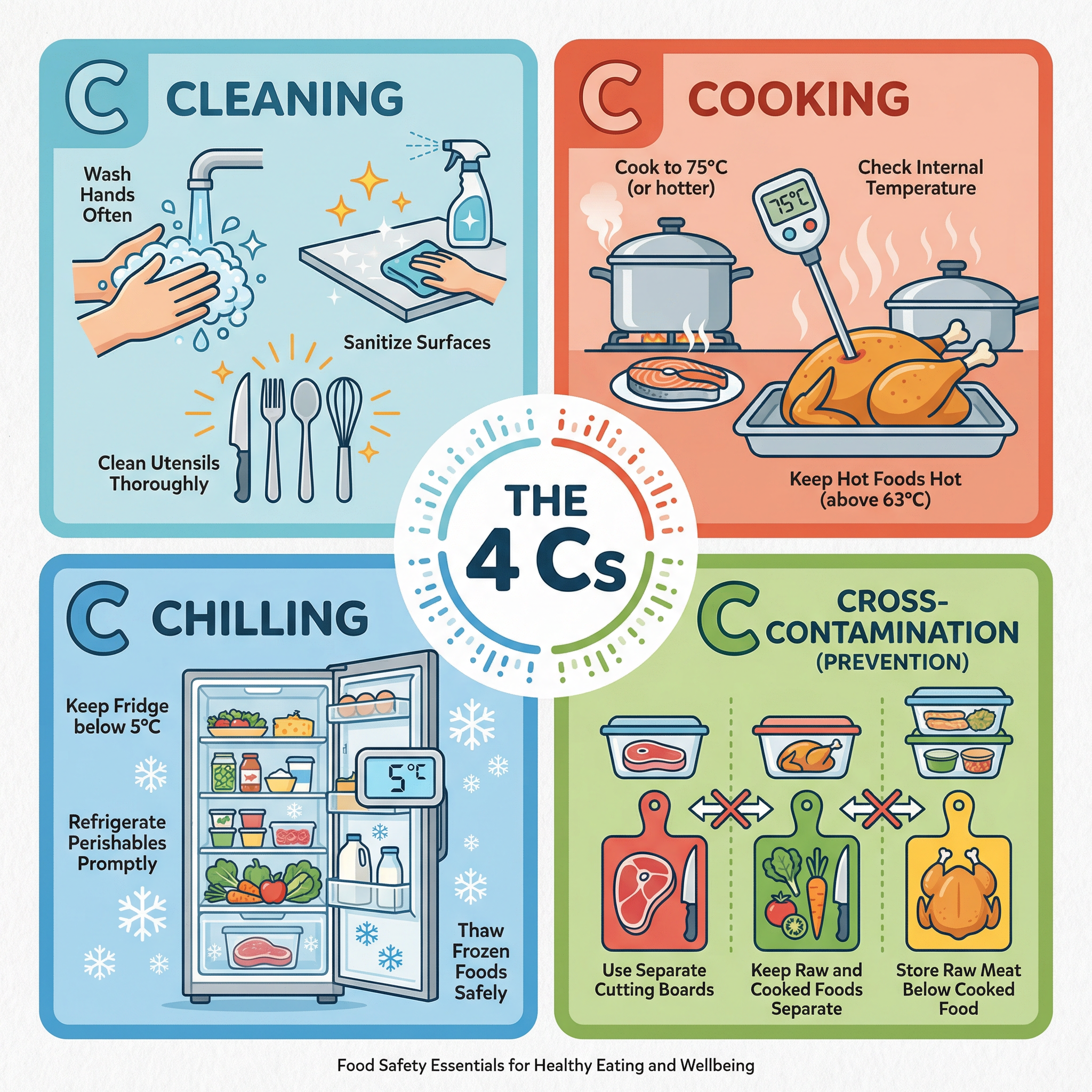

Why it matters: The '4 Cs' provide a structured framework for answering scenario-based questions. By addressing each 'C', candidates can demonstrate a holistic approach to food safety management.

- Cleaning: Involves the removal of food debris, grease, and dirt, followed by sanitising to reduce bacteria to safe levels. This applies to hands, surfaces, and equipment. Credit is given for specifying the use of hot water, soap, and a sanitiser.

- Cooking: Achieving the correct core temperature (75°C) to kill harmful bacteria. Candidates should be able to explain the use of a food probe to verify this.

- Chilling: The rapid cooling and refrigerated storage of high-risk foods to slow bacterial growth. Marks are awarded for mentioning the '2-hour rule' for cooling and refrigerating food.

- Cross-Contamination: Preventing the transfer of bacteria from a source (usually raw food) to ready-to-eat food. This is a major focus for examiners, and candidates must explain the vectors: hands, equipment, and drip.

High-Risk Foods

Why it matters: Identifying high-risk foods is a key skill. These are the foods that provide the perfect conditions for bacterial growth, and therefore require the strictest controls.

Specific Knowledge: High-risk foods are typically high in protein and moisture. Candidates must be able to provide examples:

- Cooked meat and poultry

- Cooked rice

- Dairy products (milk, cream, cheese)

- Eggs and egg-based products (e.g., mayonnaise)

- Shellfish and seafood

- Gravies, stocks, and sauces

Second-Order Concepts

Causation

Foodborne illness is caused by the ingestion of pathogenic bacteria (or their toxins) that have been allowed to multiply to unsafe levels. The primary causes are failures in temperature control, cross-contamination, or inadequate cooking. Long-term causes can include poor staff training or poorly designed food premises.

Consequence

The immediate consequence of poor food hygiene is foodborne illness, with symptoms ranging from mild discomfort to severe sickness or even death. Long-term consequences for a food business can include legal action, fines, closure, and reputational damage.

Change & Continuity

While the fundamental principles of food safety (heating, chilling, drying) have been used for centuries, our scientific understanding has changed. We now use precise temperature controls and HACCP systems instead of relying solely on traditional methods. However, the core principle of preventing microbial growth remains constant.

Significance

Understanding food safety is significant not only for public health but also for the economy. The food industry is a major employer, and maintaining high standards is essential for consumer confidence and trade. For the individual, it is a life skill that prevents illness.

Source Skills (Scenario Analysis)

In the WJEC exam, you will not be given historical sources, but you will be given scenarios. You must treat these like a source, extracting the key information and potential hazards.

How to approach a scenario question:

- Identify the Hazards: Read the scenario carefully and highlight the potential food safety risks. Are there issues with temperature? Is raw food near cooked food? Is cleaning inadequate? Categorise them: Biological (bacteria), Chemical (cleaning fluids), Physical (glass, hair).

- Analyse the Causes: For each hazard, explain what is causing it. For example, if raw chicken is stored above a salad, the cause is incorrect storage hierarchy.

- Propose Control Measures: Explain, with reasons, the corrective actions that should be taken. This is where you apply your knowledge of the 4 Cs and critical temperatures. For example, "The raw chicken must be moved to the bottom shelf of the refrigerator. This prevents juices containing Campylobacter from dripping onto the ready-to-eat salad, thus controlling the risk of cross-contamination."

- Justify your Reasoning: Always explain why your proposed solution works, linking it back to the control of bacterial growth. This demonstrates AO2 (Application) and is key to higher marks.