Study Notes

Overview

This topic explores how modern technology is fundamentally reshaping the way businesses produce goods and services. For the OCR GCSE Business exam, candidates are expected to demonstrate a precise understanding of how specific technologies like Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), Robotics, and Electronic Point of Sale (EPOS) impact the production process. Examiners are looking for more than just a list of advantages and disadvantages; they want to see clear analysis linking technology to key business concepts such as productivity, costs, quality, and flexibility. Credit is awarded for evaluating the trade-offs involved, particularly the high initial capital expenditure versus long-term efficiency gains. A crucial skill is the ability to apply this knowledge contextually, assessing whether a particular technology is appropriate for a given business scenario, from a mass-market factory to a niche, bespoke producer. Mastering this topic is vital as it provides a strong foundation for synoptic links to other areas of the specification, including finance, marketing, and human resources.

Key Technologies & Concepts

Computer-Aided Design (CAD) & Computer-Aided Manufacturing (CAM)

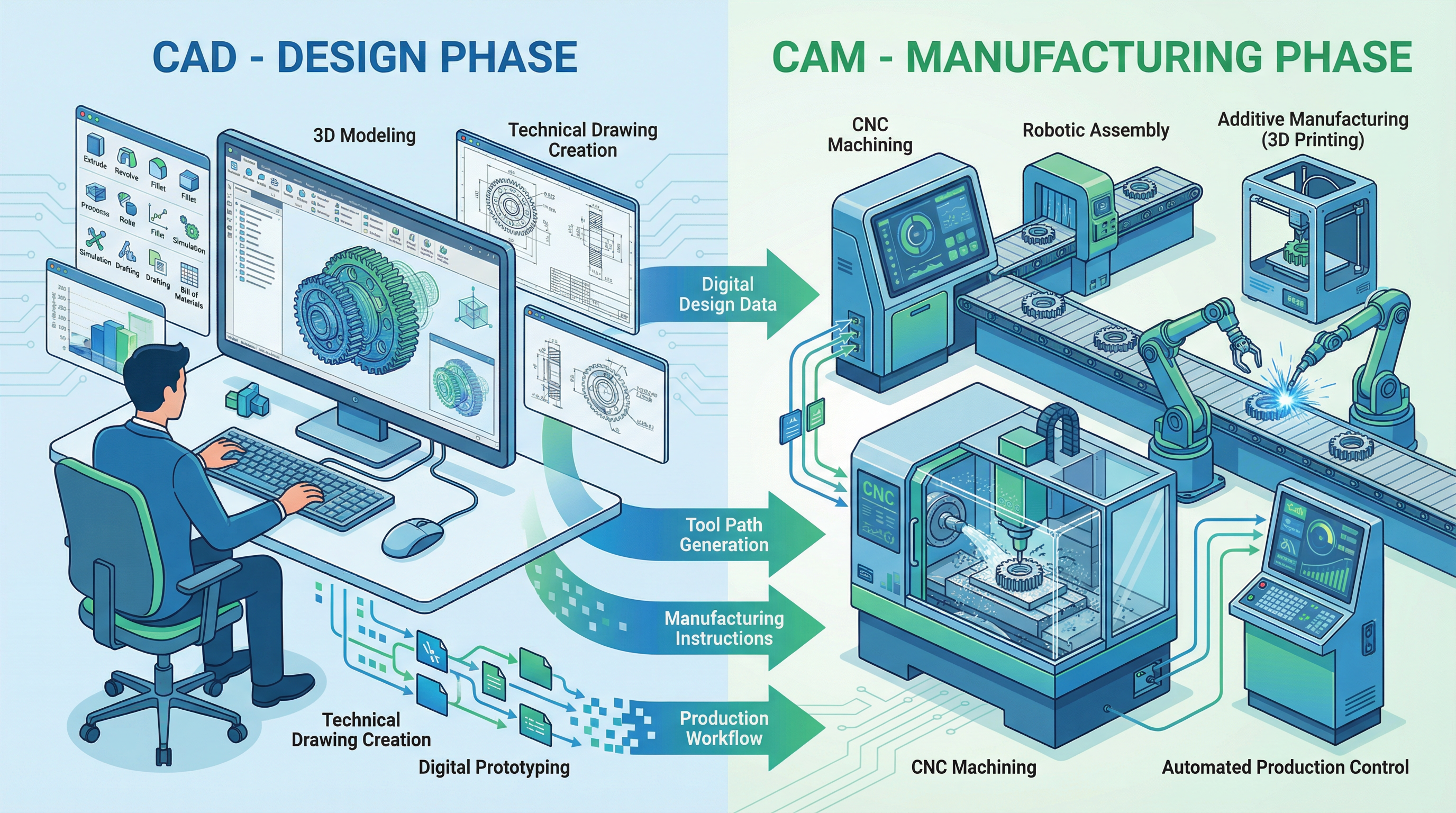

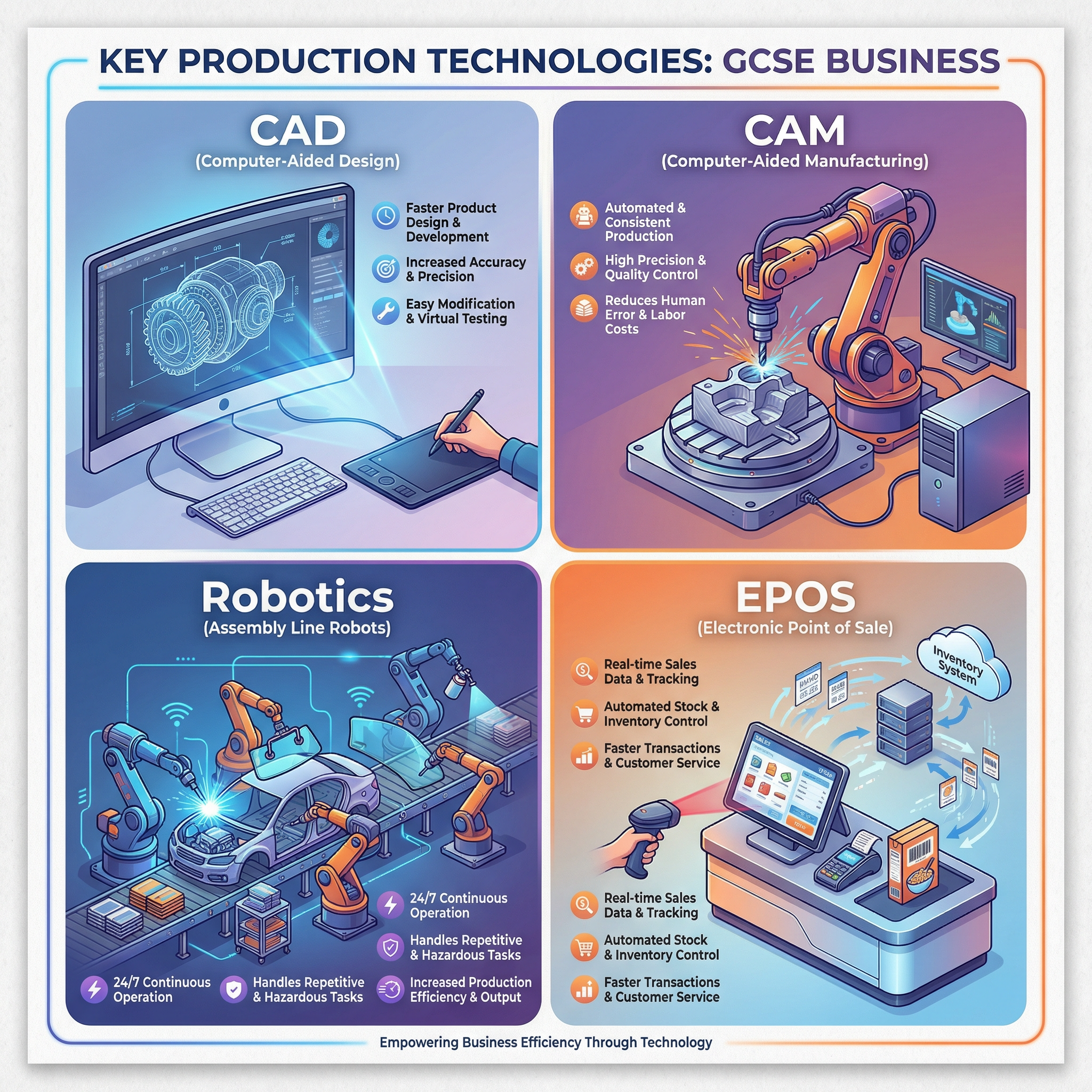

What they are: It is critical to distinguish between these two. CAD is the design phase, using software to create 2D or 3D models of a product. CAM is the manufacturing phase, using the data from the CAD model to control automated machinery that physically makes the product.

Why they matter: This distinction is a common source of confusion, and marks are explicitly awarded for getting it right. CAD speeds up the design process and allows for virtual testing, reducing waste. CAM ensures a consistent level of quality and precision that is impossible to achieve with human labour alone, operating 24/7 to increase output.

Specific Knowledge: Candidates should be able to explain that CAD allows for rapid prototyping and easy modification, while CAM controls equipment like CNC (Computer Numerical Control) machines and 3D printers.

Robotics & Automation

What it is: The use of programmable machines (robots) to perform tasks previously done by humans, especially those that are repetitive, dangerous, or require high precision.

Why it matters: Automation is a primary driver of technical economies of scale. By replacing variable labour costs with a high fixed cost for machinery, businesses can significantly lower their average unit costs as production volume increases. This is a crucial concept for analysis.

Specific Knowledge: Be prepared to discuss the high initial capital expenditure required and the potential for redundancies, which can negatively impact employee morale and the business's reputation.

Electronic Point of Sale (EPOS)

What it is: A system used at checkouts to process customer transactions. It integrates barcode scanners, card readers, and touch screens with the business's inventory and sales databases.

Why it matters: EPOS provides real-time data on sales trends and stock levels. This allows for more efficient inventory management (e.g., Just-In-Time), reduces the risk of stockouts, and provides valuable market research for production planning.

Specific Knowledge: Link EPOS to improved efficiency in stock control and its role in informing production schedules based on actual customer demand.

Second-Order Concepts

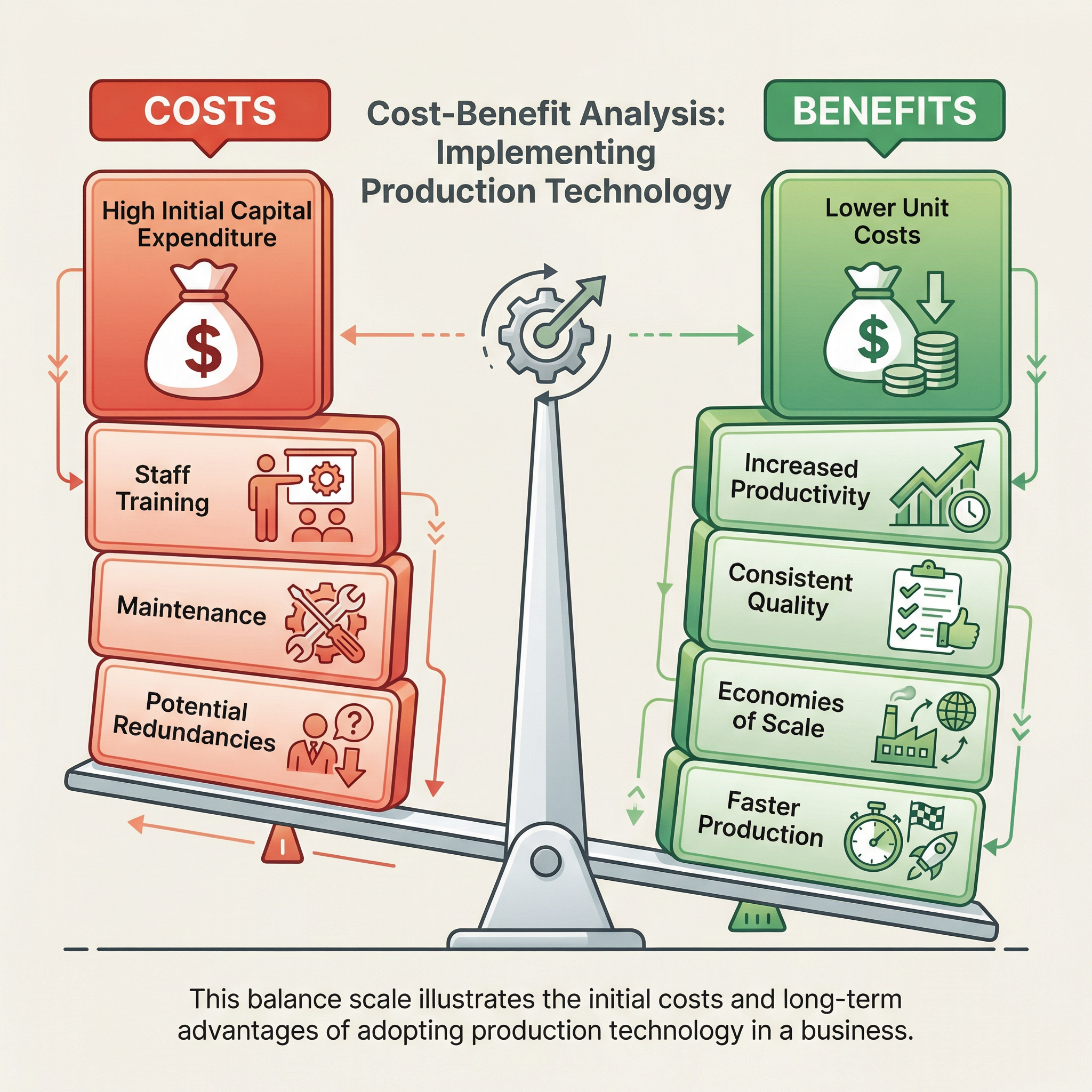

Cost-Benefit Analysis

Examiners expect a clear evaluation of the financial trade-offs. The significant upfront investment in machinery and training must be weighed against the long-term benefits of lower unit costs, reduced wastage, and higher productivity. Your analysis must consider the payback period and the opportunity cost of such a large investment.

Productivity and Efficiency

Technology directly impacts labour and capital productivity. Automation allows for a greater volume of output with the same or fewer inputs. Be specific: link CAM to fewer defects (improving quality and reducing waste) and robotics to 24/7 operation (increasing total output).

Flexibility vs. Efficiency

While automated production lines are highly efficient for mass-producing standardised products, they are often inflexible. Changing the production run to a different product can be complex and expensive. Contrast this with a more labour-intensive process, which might be less efficient but far more flexible and better suited to bespoke or customised products.

Impact on Stakeholders

An excellent way to show evaluative depth is to consider the impact on different stakeholders. Employees may face redundancy or require retraining, leading to fear and demotivation. Customers benefit from lower prices and consistent quality but may lose the option for customised products. Shareholders may see higher long-term profits but must accept the risk of the initial investment.